-

Fungus Bidon

20.00 EUR Out of stock -

Fungus Sticker

2.00 EUR Out of stock -

Protected: 1L BOTTLE CAGE (Copy)

Price range: 2.00 EUR through 44.00 EUR Out of stock -

1L BOTTLE CAGE

Price range: 2.00 EUR through 44.00 EUR Out of stock -

Adam’s H.A.T.

37.00 EUR -

No Tab Bottle Cage

Price range: 2.00 EUR through 44.00 EUR Out of stock -

Std Bottle Cage

Price range: 2.00 EUR through 44.00 EUR Out of stock -

Drop Shadow Bidon

20.00 EUR Out of stock -

Crackpipe Lightmount

40.00 EUR Out of stock -

Frame Deposit

1,000.00 EUR Out of stock

About Hulsroy Cycles

I am Mads Hulsrøj Jæger.

I graduated from architecture school in 2013 but I have always been a maker, and during my education I was bitten by metal work. Seeking more than the shallows of architecture had to offer, I began to explore the process behind how things are made, and above all how things are made well. This lead me to take a break from architecture school and study precision mechanics. Here I learned to work with metal in a professional way.

After my return to architecture and my graduation project, I started defining an approach to making, and more specifically frame building. Self reliance and learning through free knowledge were the key principles, fueled by the ever expanding online bicycle forum community. By sharing my process with a mix of jaded professionals and eager enthusiasts, I received loads of support, valuable advice and some good offers along the way. The end result was a steel cargo bike – the ultimate symbol of self-reliance and independence, as well as living proof that you can accomplish a lot if you seek out the knowledge. In this way it became my story to design, build, and share.

I believe that bicycles are important. Especially simple and beautiful bicycles made by human hands. In all my work I aim to have a sustainable approach: quality not quantity.

But that’s not all. It’s also about getting out there on your bike, and spreading the joy to as many people as possible. It’s about spending time with friends and having long deep conversations on the bike. It’s about finding the adventure and expanding your horizon, as well as the enjoyment of nature and getting a break from the real world.

My mantra is “KØRDØR”, translated to ‘ride til you die’ or ´ride you buffoon´ – it sort of has two meanings in Danish. And it’s hard to explain the duality.

KØR TIL DU DØR was written on the tarmac at the top of a gnarly climb calle dPøt Mølle. As I reached the top of the climb, at a moment of exhaustion, I realised what cycling meant to me. I sincerely hope I can ride until I die. And that all my friends and family can too. It’s obviously not what the author of the statement meant, but it’s what I took from it – Cyling Momento Mori.

Process

IS CUSTOM FOR ME?

Production frames can be absolutely amazing. If you can find a frameset with the right specs and geometry for you – go for it!

What I offer is what you can’t neccesarily buy. It could be an exact geometric copy of a CAAD10 roadbike but with slightly more stack or it could be a deep custom touring bike with quirky components and custom dropouts. Personally I’ve never been able to make an off the peg frameset work aestetically with my fit preferences. That’s why I decided to make my own frames.

I can guide you to a type of bike that will suit you and your riding style and I am happy to advice on components and geometry choices (in terms of handling), but I always suggest you start out your custom bicycle adventure by visiting a trustworthy bike fitter. If you already know what works for you, great – then we can get started.

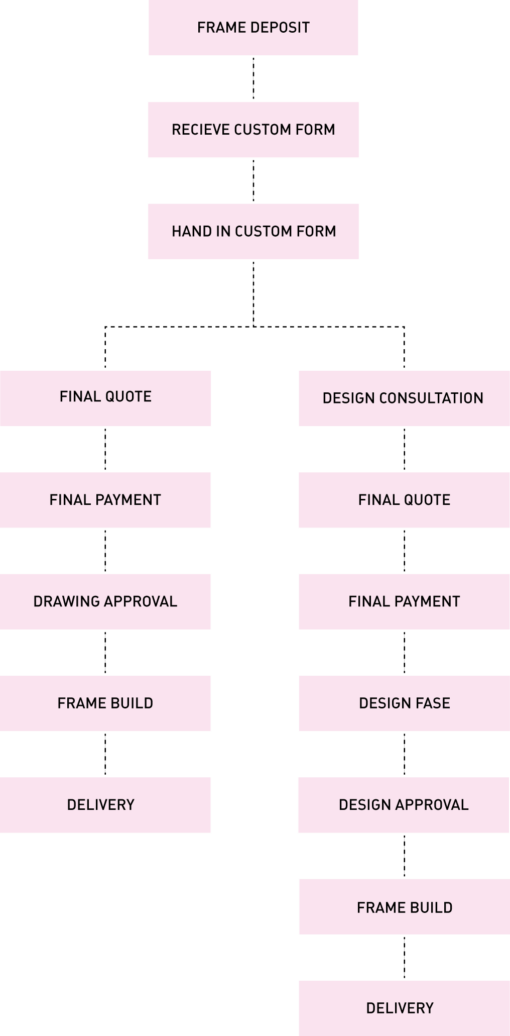

THE ORDER PROCESS

I need to take a frame deposit to be able to start the conversation with you. This will be deducted from the final quote but gives you a slot in the build cue. I only do one bike at the time at the moment and lead times vary depending on the complexity of the build and custom parts needed. If you put down a deposit today you should be able to have a working bike within a year.

If you know exactly what you want and just want me to fabricate a frame to your desired specs we can fast track to you receiving a 2D drawing and me choosing details based on your custom form.

Currently I only offer fillet brazed (and filed) steel or stainless steel frames.

Design Consultation

If you’d like me to help out with styling, colour and component choices etc. I also offer design consultation. We can do this face to face in my workshop in Aarhus or via Zoom or similar online services.

A part of the the design fase is that you receive 3D visualisations for your approval before we embark on building the frame.

I am happy to facilitate a complete build if you’d like. I collaborate with a great bag maker and amazing wheels builders.

Deeeeeeep Custom

If you really want something unique I have a lot of experience designing for both 3D printing and CNC machining and would be happy to talk about special frame components.

I also offer my cad skills for other frame builders and manufacturers. So if you want help designing and developing components or bike concepts, for someone else to fabricate, my services are available.